FCR?

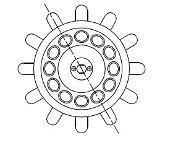

Relative Centrifugal Force, also known as “xg”, is calculated based on the rotor radius and its speed (RPM: Revolutions Per Minute at which the rotor rotates).This data must be taken into account when working with glass tubes. If the rotor is programmed at more RCF than the tube can withstand, cracks and / or breaks will occur. Check the characteristics of the tubes you are going to work with to make sure you program the correct FCRs.

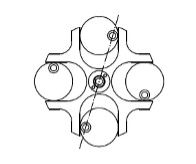

ULS (Unbalance Location System)?

PCBS (Progresive Control Braking System)?

Free braking?

Start delay?

Linked program?

GRS (Gas Release System)?

Pre-cooling program and what are its uses?

It is used to reach the selected temperature in the chamber before spinning. As it depends on the characteristics of the rotor, only the temperature to be reached must be selected, since the rest of the values are automatically defined.This process will occur with the rotor turning, but as it is not part of the centrifugation, in no case should the samples be introduced.

Once the pre-cooling program has been run, the samples will be placed in the rotor for centrifugation. After the spin cycle, the centrifuge will maintain the selected temperature until it goes into stand-by mode or the lid is opened.