The process of choosing a centrifuge can be complex, as there are many basic variables to consider if you want to make a good choice.

The simplification of this task is essential to allow the user to identify the equipment needed based on not just some variables, but also considering their preferences. To facilitate this work, we have defined this guide for choosing centrifuges, taking into consideration some of the characteristics of the equipment to serve as guides to refine the search based on manners of working.

The basic information needed to start is the following:

- Characteristics and properties of the tubes to be processed: length, diameter and RCF tolerance.

- Maximum required speed and max. RCF: what do the max. RPM or RCF (xg) you want to work with depend on?

- Number of tubes to be processed per cycle: also called number of positions.

- Type of centrifuge according to temperature control: refrigerated, heated, ventilated.

- Type of rotor required: angle fixed o swing out, decisive for obtaining the separation result.

- Other technical characteristics: the combination of all of them will define the equipment required.

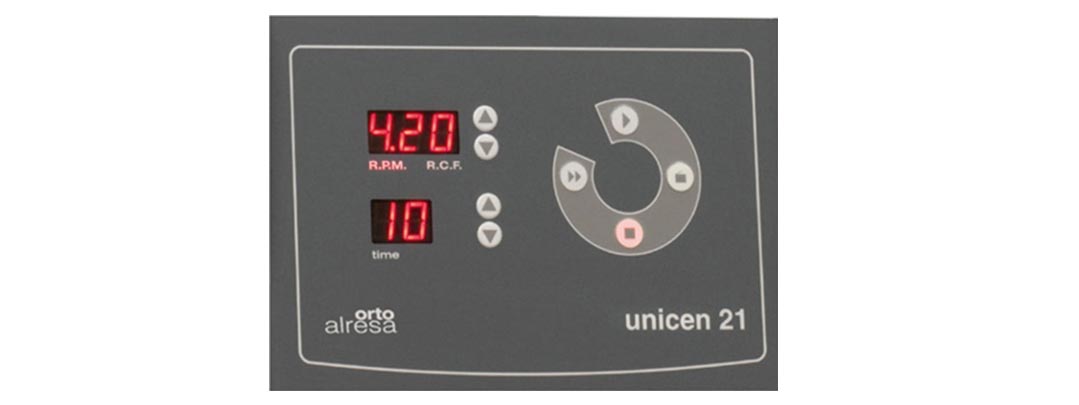

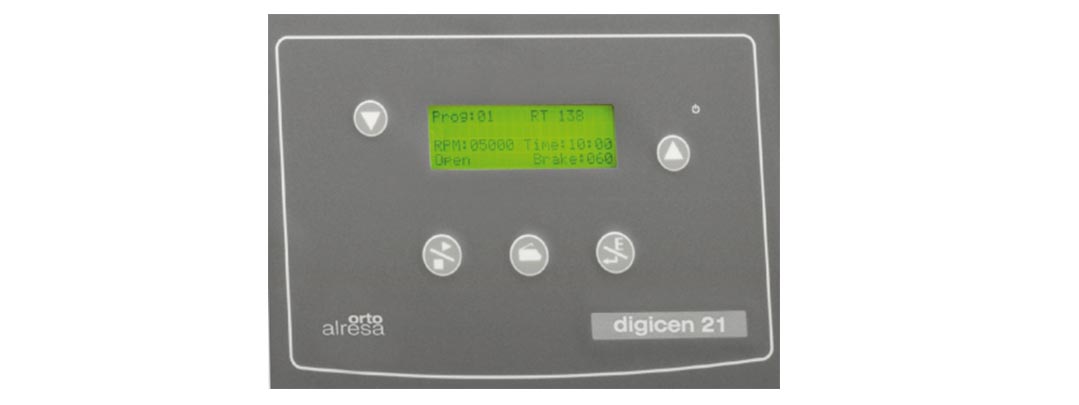

- Type of equipment control: type of screen included in the centrifuge.

You can get more information about any of these parameters checking the menu on the left.