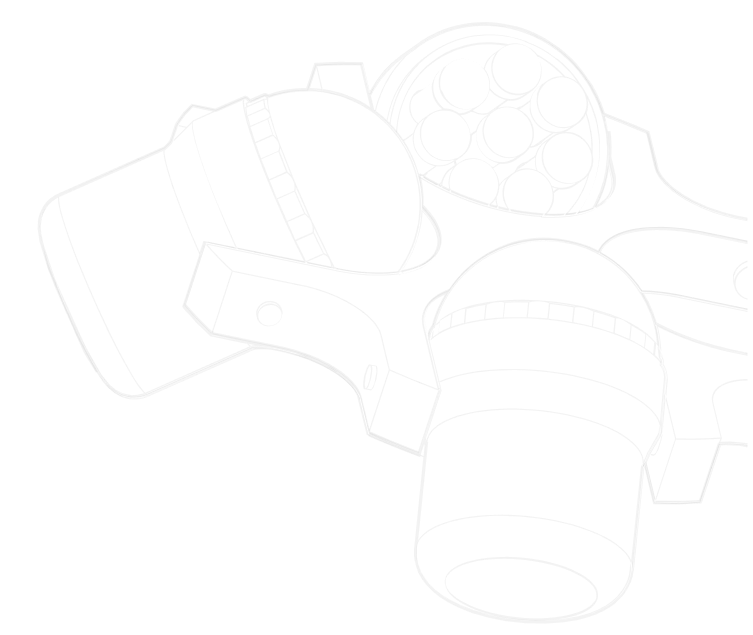

The centrifuge Lacter has been designed for the handling of dairy products such as milk, cheese, cream, yogurt and its derivates easily and accurately.

Its design allows it to process Gerber or solubility tubes. It has 16 programs that allow to store the parameters to analyse samples of different types of animals reducing the processing time.

The smooth operation prolongs the tubes life and prevents their breakage. The simultaneous and automatic conversion of RPM/FCR values eliminates additional calculations and the heating system ensures temperature traceability throughout the process.

Features

Maximize

Minimize

Heated:working temperature up to 80 °C (176 °F).

LCD screen:

- Shows RPM and RCF, time, temperature and acceleration/deceleration (PCBS).

- Speed programming in 10 RPM/ 10 xg steps.

- Timer countdown/up from “0” or at “set RPM/ RCF” for reproducible tests.

- Timer: from 5 sec. to 99 minutes or from 1 min. to 99 hours and indefinite time.

- PCBS: : Progressive controlled braking system up to 175 selectable ramps that prevents sample homogenization after separation.

- 16 programmable memories.

- Several acoustic and visual messages showing the user the situation of the device.

Easy to use

Maximize

Minimize

- Microprocessor controlled.

- Induction motor maintenance free (brushless).

- Rotors list on memory.

- Noise level: below 60 dB.

- Start, stop, open lid and short spin with adjustable speed buttons.

- Option of free/locked adjustment of RPM/ RCF along the run.

- Last values remain in memory.

- Low height for easy acces.

- Automatic rotor recognition. Over-speed protection.

Safety

Maximize

Minimize

- Lid provided with security systems:

– Automatic lid lock system, motorized with double lock.

– Emergency lid-lock release.

– Locking and protection against opening along the run.

– Lid dropping protection.

– Port in the lid for calibration and operation checking.

- Ergonomic design that allows close the lid effortless.

- Unbalance detection and switch off.

- Protection safety ring between the centrifugation chamber and the housing.

- Chamber of centrifugation in stainless steel (easy cleaning).

- Rotors and adapters autoclavable, easy to install by the user.

- Automatic disconnection for energy saving up to 8 h.

Heating

Maximize

Minimize

- Preheating program with rotor spinning and selectable temperature. It allows keeping the chamber at working temperature before starting the process.

- Regulation of the room temperature +5°C (41°F) to 80°C (176°F) in 1°C/1°F steps. Programmable in °C o °F.

- Temperature sensor inside the chamber. Overheating protection.

- Internal isolated avoiding heat loss.

Standards and Directives

Maximize

Minimize

EU Directives: 2011/65/EU, 2012/19/EU, 2014/30/EU, 2014/35/EU.

Standards: EN 61010-1, EN 61010-2-101, EN 61010-2-020, EN 61326-2-6,EN 61326-1, EN 61010-2-010.

Versions

Maximize

Minimize

| Code | Dimensions (mm) (w x d x h) | Net weight (Kg) | Voltage (V) | Frequency (Hz) | Consumption (W) | Heating |

|---|---|---|---|---|---|---|

| CE 158 | 410x520x380 | 41 | 220-230 | 50-60 | 500 | Si |

| CE 159 | 410x520x380 | 41 | 110-120 | 50-60 | 500 | Si |